The wool knitted in our workshops comes from Australia, New Zealand, and South America. It is exclusively pure new wool, which means it comes directly from the shearing of healthy, living sheep. Inferior quality wool, which we do not use, is recovered from the fleece of slaughtered animals.

Raw wool, collected during shearing, is still greasy to the touch due to a fat secreted by sheep's skin. Therefore, it must be washed. Between raw wool and clean wool, it takes about 40% loss. So, for 1 kg of clean wool, 1.8 kg of raw wool is necessary.

The wool is washed, which removes the oils, dust, soil, and plant debris it still contains. The next step is carding, which involves disentangling the wool using a tool called a card.

Once carded, the wool is freed from the largest plant residues. The combing step allows finer pollution to be extracted. The yarn then comes out in the form of ribbons, which will then be dyed.

Two different techniques are used for dyeing wool. If the quantity of wool is at least equal to 1,000 lbs, the ribbons are directly immersed in large dye tanks. If the amount is smaller, the yarn is first spun, then wound onto cones before being dyed.

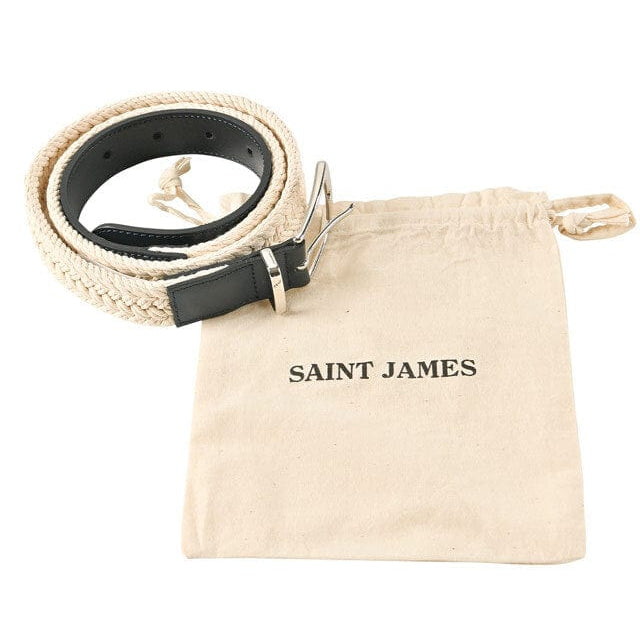

The wool used for Saint James clothing is spun in Europe, mainly in Italian spinning mills. It arrives in our workshops in the form of cones. The quality of the yarn is controlled meticulously by the knitting engineers, who then use it to feed the knitting machines.

The wool is stored in our workshops under strict conditions, at constant humidity and temperature levels.

In 2020, Saint James joined the French Tricolore collective. This organization aims to promote and rebuild the French wool industry, ranging from sheep shearing to knitting, including the various stages of washing, carding, combing, and spinning. Two styles, a men's sailor sweater, and a women's Breton sweater, were launched to celebrate this initiative with the SS21 Collection.